Metal cutting, rolling and bending

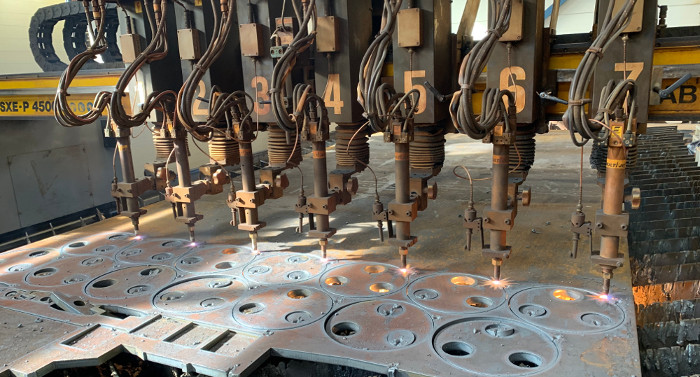

Plasma and gas cutting

Plasma cutting is mostly used on 2-20 mm thick metal, which allows you to cut out parts quickly and precisely. With gas, we cut thicker and stronger materials, mostly 20-300 mm thick. With our 7-headed gas burner, both small and large series can be cut quickly and flexible.

Plasma cutting is thermal (up to approx. 30000 °C) metal cutting, which is a very common form of sheet metal processing. The principle of plasma cutting is to heat the metal and then blow it out. Plasma cutting can be used to cut out details of different sizes, shapes and thicknesses, with or without holes. It is particularly well suited for cutting medium-sized metals up to 40 mm thickness. The advantage of plasma cutting is its speed. Also, such a cutting method does not cause metal deformation, i.e., the cut edges remain smooth and do not require afterward treatment.

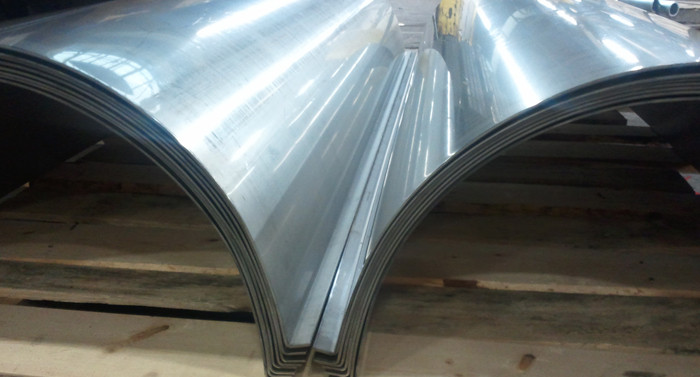

Metal rolling

We roll plate iron up to 2000 mm in width and 3-20 mm in thickness. Rolling is a process where metal plates are passed through rolls in order to reduce the thickness and to give the metal another form. There are two ways of rolling, hot rolling and cold rolling. We use cold rolling. Rolling processes are classified as follows:

- Roll bending

- Roll forming

- Flat rolling

- Ring rolling

- Controlled rolling

- Forge rolling

Ask for a quote!

We will respond to requests already on the same working day!

To get a quick request, call +372 588 46945